Basic parameters

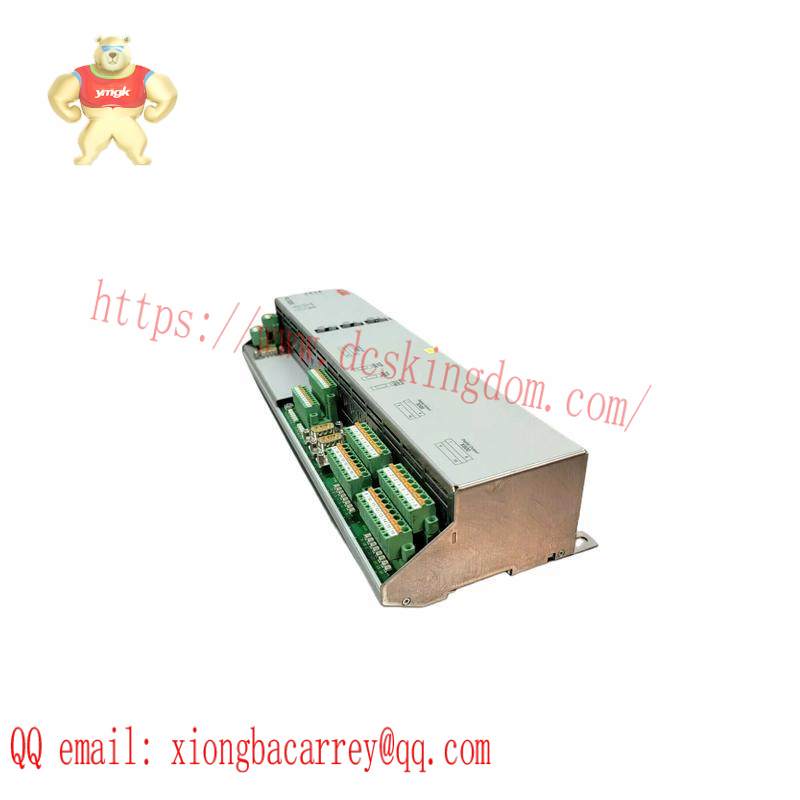

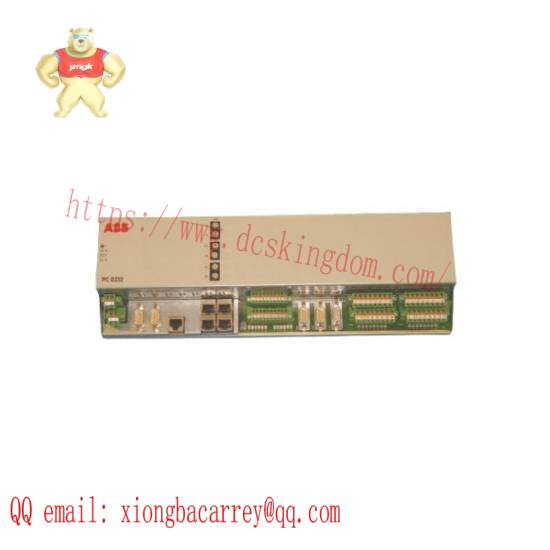

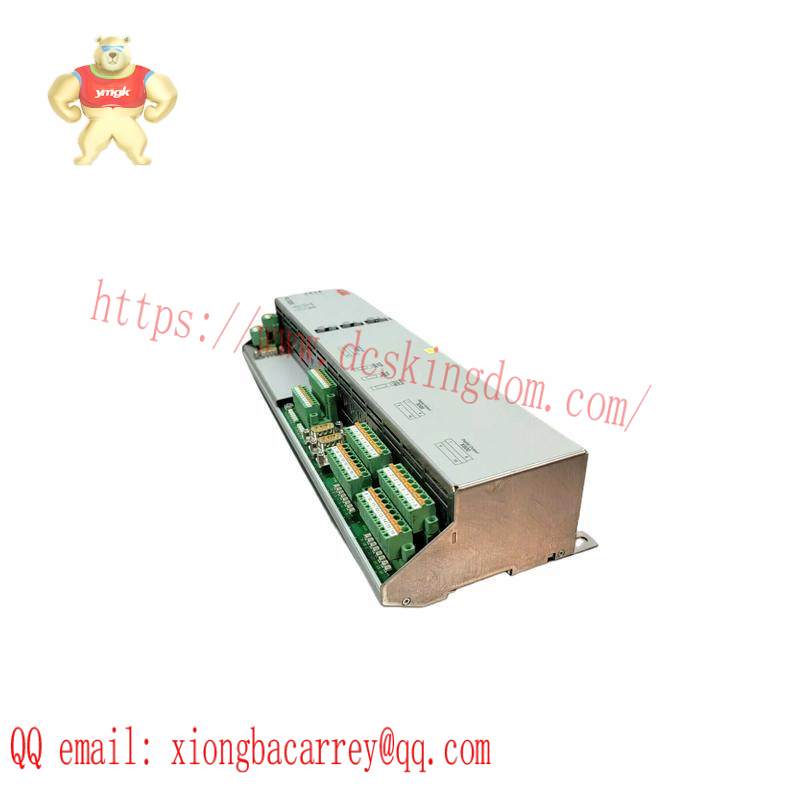

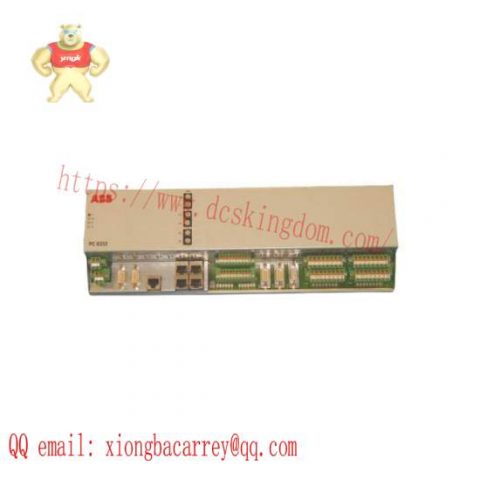

Model positioning: static excitation control module in ABB UNITROL series, modular digital exciter.

Input voltage: 100-240 V AC, input current 10-20 A.

Output voltage: 0-200 V AC, output current 0-20 A.

Insulation level: IP65, operating temperature range -25℃ to 60℃.

2. Core functions

Excitation control:

Maintain generator voltage stability through PID controller and support reactive power compensation.

The digital output module provides control signals, drives the excitation winding and monitors the equipment status.

Monitoring and protection:

Rotor overvoltage protection: BOD board detects overvoltage, triggers the jumper to conduct, and consumes energy in the demagnetization resistor.

Demagnetization function: inverter demagnetization during normal shutdown, and quickly cuts off the excitation current during accident shutdown.

V/Hz limit: prevent excessive voltage at low frequency and protect the core flux density.

Communication capability:

Supports Ethernet, USB, RS232/485 interfaces, compatible with Modbus, Profibus and other protocols.

Can be integrated into ABB AC450/AC800PEC system to achieve cloud remote monitoring.

3. Hardware configuration

Processor and memory: 32-bit CPU, 128MB memory, to ensure fast execution of complex algorithms.

Analog input channel: Eight-channel analog voltage input, supports -5V to +5V or -10V to +10V dual mode, resolution of 0.2mV (5V mode) or 0.4mV (10V mode), accuracy 0.05%.

II. Application scenarios and typical cases

1. Power industry

Yangxi Power Plant: UNITROL 6800 system is applied to 600MW units to achieve efficient excitation control.

Shenzhen Mawan Power Plant: Static excitation improves the response speed of the power grid and supports static excitation.

Fault case: A power plant tripped due to overexcitation due to slow melting of TV primary fuse, which was later solved by replacing spare parts and optimizing the protocol.

2. Industrial Automation

Electrolysis process: Support IDC current step compensation and power factor correction to improve copper/zinc electrolysis efficiency.

Railway transportation: Drive motor control, such as railway traction system, to ensure stable operation.

3. Renewable energy integration

Wind farm: Maintain voltage stability of wind turbines and adapt to fluctuating inputs.

Microgrid: Realize voltage and reactive power regulation in distributed energy systems to improve grid resilience.

Troubleshooting and maintenance guide

1. Common problems and solutions

Analog input abnormality: Check the on-site wiring contact and confirm the channel configuration (such as voltage range, resolution).

Communication failure: Verify protocol settings (such as Modbus address, baud rate), and check the physical interface (RJ45/RS485).

Excitation instability: Calibrate PID parameters and check the power module temperature sensor.

2. Maintenance tools and processes

Remote diagnosis: adjust parameters through ABB CMT tool or handheld programmer (SPA).

Spare parts replacement: COB and MUB boards support hot swapping, and the mean time to repair (MTTR) is less than 2 hours.

Regular inspection: TV primary fuse, cooling fan and other key components.

Summary

ABB 7625013-S control unit continues to play a key role in the power and industrial fields with its high-precision control, modular design and high reliability.

Related product recommendations:

1TGE120011R2200

RMU610 2VAA008425R1

CHBX01L 2VAA008574R1

CHBX01R 2VAA008575R1

3BUS208796-501

PM645B

UNITROL1010 3BHE035301R1002

3BHE035301R1002

UNITROL1010 3BHE035301R0001

3BHE035301R0001

XVC517AE10 3BHB004744R0010

3BHB004744R0010

UFC760BE41 3BHE004573R0141

3BHE004573R0141

S-053M 3BHB012897R0003

3BHB012897R0003

PPD517A3011 3BHE041576R3011

3BHE037864R0106

UFC911B106 3BHE037864R0106

LDMTR-01 63940135F

More……

There are no reviews yet.