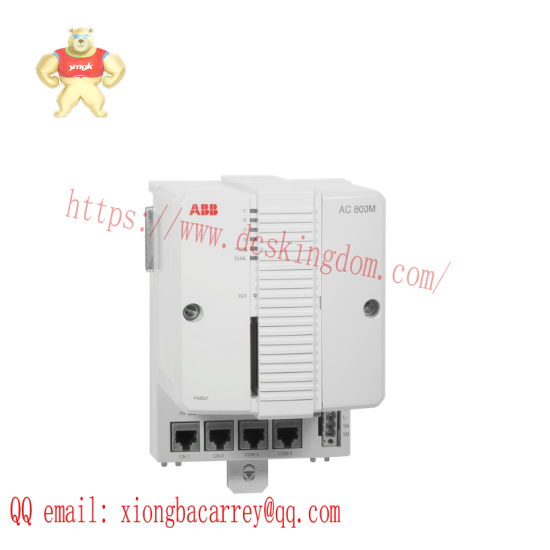

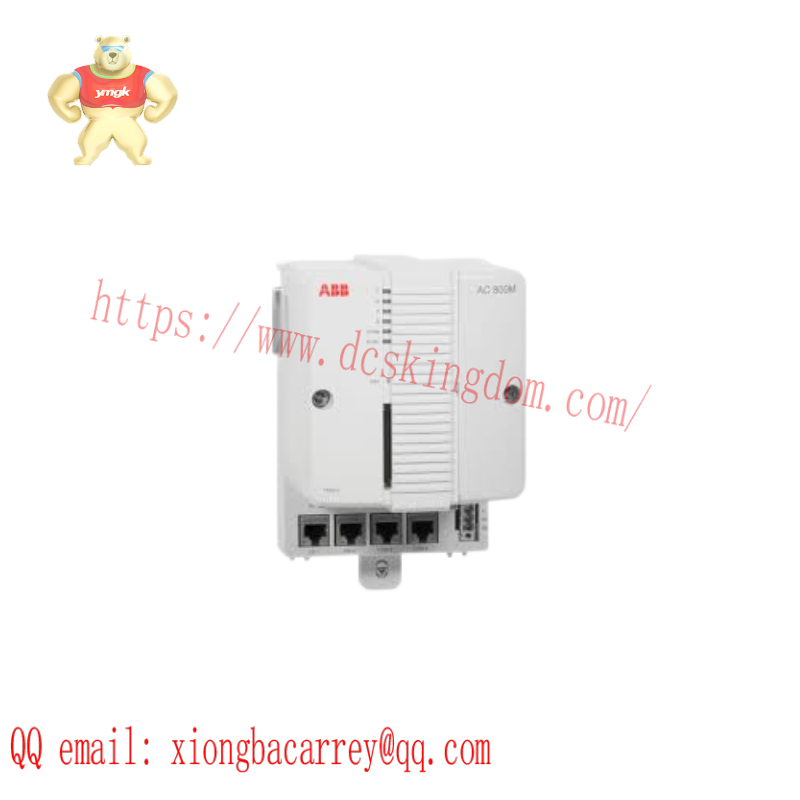

Technical Specifications

Processor Architecture:

Using 32-bit DSP (digital signal processor) chip, the main frequency is up to 200MHz, supporting high-speed data processing and real-time control algorithms.

Memory Configuration:

Equipped with 256KB RAM for dynamic data storage to ensure efficient data processing during system operation.

512KB Flash is used to solidify programs and parameters to ensure the stability and reliability of system operation.

I/O Capability:

Supports 32-channel digital input/output (DI/DO), compatible with a variety of voltage signals (such as 24VDC), and meets diverse digital control needs.

Integrated 8-channel analog input/output (AI/AO), supports standard current/voltage signals (such as 4-20mA, 0-10V), suitable for the collection and control of analog signals.

Communication Interface:

Dual protocol support, including RS-485 (supports Modbus and other protocols) and Ethernet (adapts to TCP/IP, EtherNet/IP and other industrial networks), to achieve communication and integration with different devices and systems.

With multiple serial ports and Ethernet communication ports, the communication capability is further enhanced.

Modular structure:

Adopting standardized size design, supporting hot-swap function, facilitating system expansion and maintenance.

Protection level and working environment:

Meet the industrial-grade IP20 protection standard, with strong anti-electromagnetic interference ability, suitable for harsh industrial environments.

Wide operating temperature range, from -25℃ to +70℃, ensuring stability under extreme conditions.

Redundancy and fault tolerance:

Supporting redundant communication equipment, improving system fault tolerance, ensuring that when the main module fails, the system can automatically switch to the backup module to ensure continuous operation.

Self-diagnosis function:

Built-in self-diagnosis function, real-time monitoring of module status and reporting of fault information, facilitating timely discovery and resolution of problems.

Programming compatibility:

Supporting mainstream configuration software such as ABB Control Builder, simplifying the system integration process and improving development efficiency.

Functional features

High-performance processing:

Powerful processor performance can quickly perform various complex calculation and control tasks, ensuring the real-time and accuracy of the system.

Rich interface configuration:

Provide a variety of communication interfaces and I/O channels to meet the data transmission and control needs in different scenarios.

High reliability and stability:

Adopting industrial-grade design, it has good anti-interference ability and stability, ensuring long-term stable operation in harsh industrial environments.

Easy to expand and maintain:

Modular design supports hot-swap function, which is convenient for system expansion and maintenance, and reduces maintenance costs.

Intelligent diagnosis and remote monitoring:

Built-in self-diagnosis function, supports remote status monitoring and maintenance, and reduces the risk of equipment downtime.

Application scenarios

Industrial automation and process control system:

As the core component connecting different types of I/O modules, communication modules and control devices, it realizes data transmission and real-time control, and is widely used in various industrial automation scenarios.

High-speed production line control:

Such as automobile manufacturing, electronic installation, etc., use high processing speed and multi-channel parallel processing capabilities to achieve equipment linkage and process monitoring, and improve production efficiency.

Motor control:

Integrated motor encoder signal processing, support vector control algorithm, achieve speed/torque adjustment, seamlessly connect with inverter and servo drive, and optimize motor energy efficiency management.

Process control:

In industries such as petroleum, chemical, and electric power, process variables such as temperature, pressure, and flow are collected through AI/AO channels to achieve closed-loop control and ensure the stability and safety of the production process.

Distributed control system:

As the core interface of the distributed control system, it connects sensors, actuators, and HMI devices to achieve collaborative work and remote monitoring between devices.

Market positioning

ABB processor unit SPBRC400 is positioned in the mid-to-high-end industrial automation market, suitable for scenarios requiring high reliability, scalability, and safety certification. With its powerful processing capabilities, rich interface configurations and industrial-grade design, the processor unit demonstrates wide adaptability in the field of automated control and can meet the needs of different industries for high-performance industrial automated control modules.

Related product recommendations:

SHINKAWA VM-5Y1-02

ABB 3BSE003911R0001

ABB 3BSE004724R1

ABB SPAM150C RS641006

ABB 3HAB2071-13, 5

ABB SNAT 603 CNT 5761861-2B

ABB TB840

ABB 3BSC820010R1

ABB 3BHE031734R1011

ABB 3BHB002916R0001 UFC721AE

ABB 3HAC10098-1

ABB PM865 3BSE030193R1

ABB DSQC406 3HAC035301-001

ABB SPAJ140C

More…

There are no reviews yet.