Core Overview

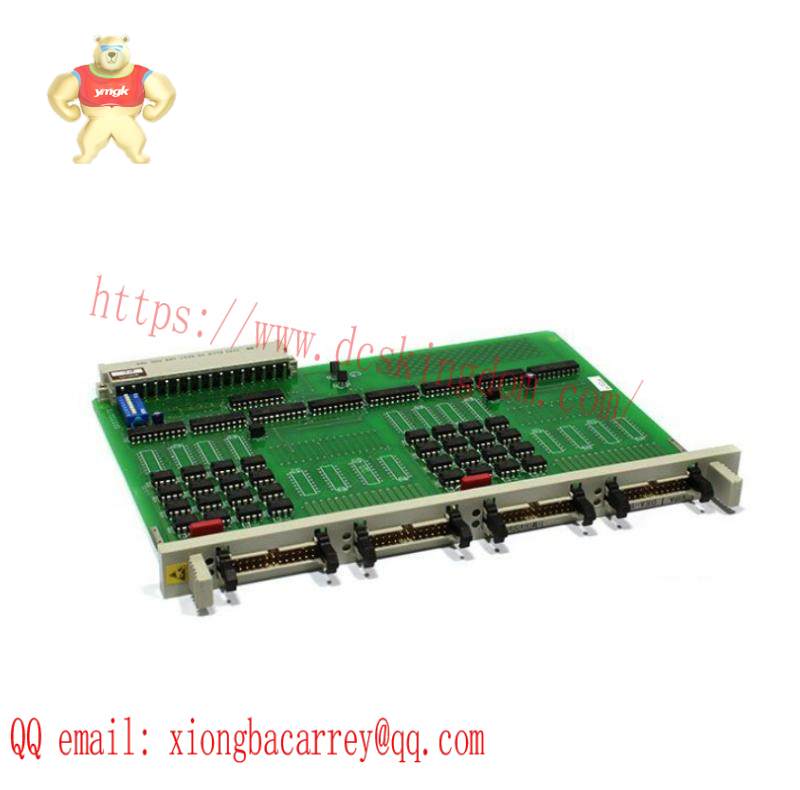

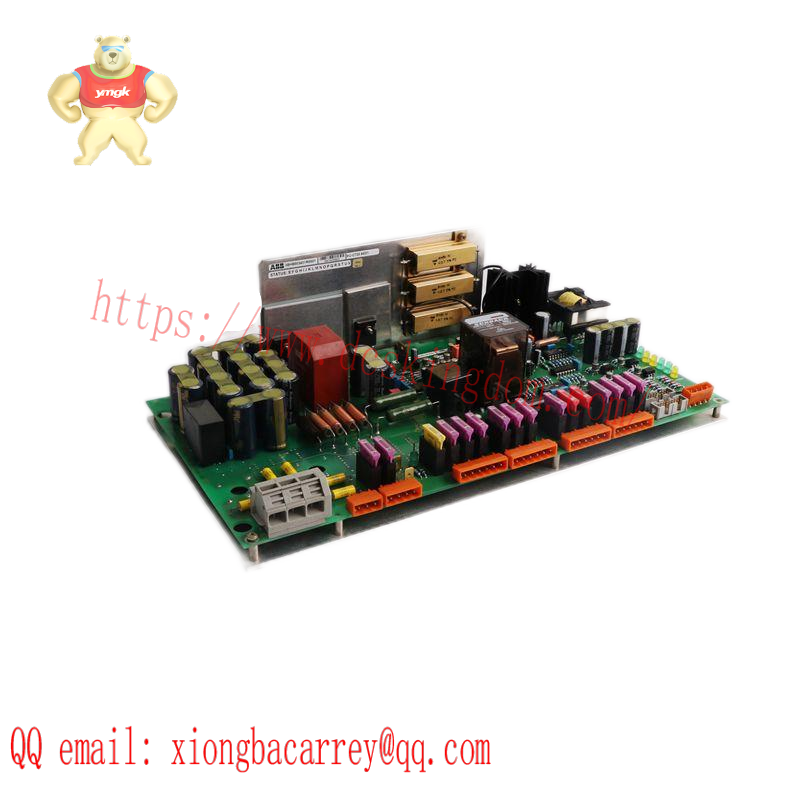

The ABB ACS6000 is a high-performance medium-voltage frequency converter employing Direct Torque Control (DTC) technology. It is suitable for motor drives (such as rolling mills, compressors, pumps, and fans) in industries such as metallurgy, shipbuilding, oil and gas, and mining. Its control unit (COU) is the core of the system, responsible for rectifier/inverter unit coordination, fault diagnosis, and dynamic control, supporting single-motor or multi-motor redundant configurations.

Technical Characteristics

Efficiency and Power Factor: Efficiency >98%, power factor up to 1 (active rectification) or 0.95 (diode rectification), compliant with IEEE 519 harmonic standards.

Voltage and Power Range: Input voltage 3300V/1725V, output power 3000kW-36000kW, compatible with induction/synchronous/permanent magnet motors.

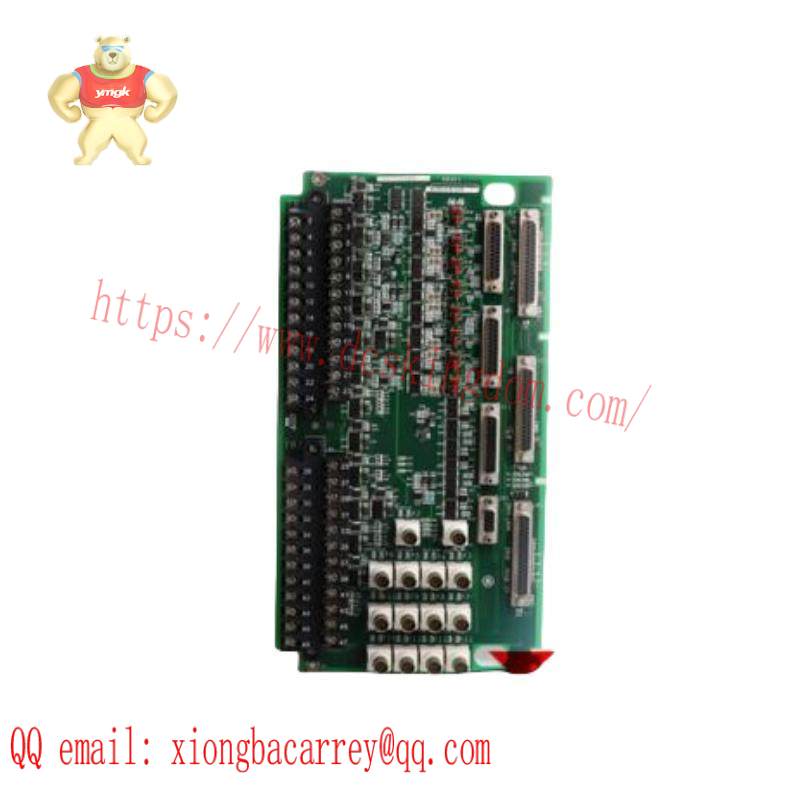

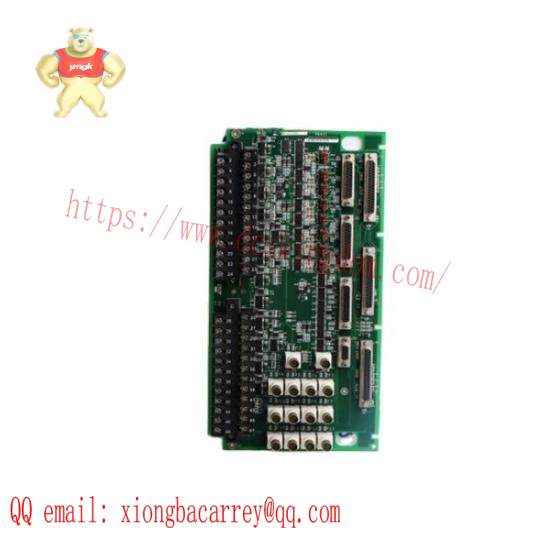

Modular Design: Includes modules such as ARU (active rectifier), INU (inverter), CBU (capacitor), COU (control unit), and WCU (water-cooled unit), supporting flexible expansion.

Cooling System: Water-cooled design, requiring external cooling water temperature of 5-32℃ (downscaled to 40℃), conductivity <0.5μS/cm.

Application Scenarios and Advantages

Industrial Sector:

Metallurgy: Rolling mills, mine hoists, achieving precise speed/torque control.

Marine: Main propulsion systems, auxiliary machinery, supporting four-quadrant operation and emergency reverse.

Energy: Compressor and pump loads, with significant energy-saving effects (e.g., the 101MW inverter case in the NASA wind tunnel project).

Performance Advantages:

Fast dynamic response (control cycle 4000 times/second), torque fluctuation <1%.

Supports power failure crossing (maintains operation during voltage drops), reducing downtime losses.

Modular redundant design improves system availability.

Maintenance and Troubleshooting

Common Faults: Abnormal DC bus voltage, overcurrent/overtemperature alarms, cooling system failures (e.g., excessive conductivity).

Diagnostic Tools: Use DriveWindow software to read fault logs and analyze parameters (such as EPLDFirst fault), and monitor current/voltage waveforms with an oscilloscope.

Maintenance Points: Regularly check the conductivity and capacitor status of the water cooling system, and update firmware (such as upgrading the AMC3 board).

Recommended related products:

ABB AC 800PEC series controller PM865K01 3BSE031151R1

ABB AC 800PEC series controller PM866-2 3BSE050201R1

ABB AC 800PEC series controller PM866A 3BSE076359R1

ABB AC 800PEC series controller PM866K01 3BSE050198R1

ABB AC 800PEC series controller PM891 3BSE053240R1

ABB AC 800PEC series controller PP825 3BSE042240R1

ABB AC 800PEC series controller PP825A 3BSE042240R3

ABB AC 800PEC series controller PP836 3BSE042237R1

ABB AC 800PEC series controller PP865A 3BSE042236R2

ABB AC 800PEC series controller PP875 3BSE092977R1

More……

There are no reviews yet.